Fraunhofer ENAS

The Fraunhofer Institute for Electronic Nano Systems ENAS focuses on applied research for the development of smart integrated systems. The institute offers research and development services from the idea, via design and technology development up to tested prototypes. Its department MMC is a leading center for micro materials reliability.

The particular strength of the Fraunhofer Institute for Electronic Nano Systems ENAS lies in the development of smart integrated systems for different applications. These systems combine electronic components with nano and micro sensors as well as actuators, communication units and self-sufficient power supply. The department MMC has a long-standing experience in DfR methodologies for thermo-mechanical reliability of micro-systems.

Currently its work is dedicated to reliability methodologies during the design, development and testing of intelligent (power) electronic systems consisting of sensors, actuators and electronics along the value chain. The simulation-based methods are being developed up to "digital twins" and the methods of AI will be included in this process, which represent one of the challenges of the digital transformation in the electronics industry, which is dealt with in particular on questions of reliability and product robustness.

Role

The department MMC, partner of the iRel4.0 project, focuses on the pro-active 'design for reliability' based on 'physics of failure' and virtual prototyping methods concerning thermo-mechanical reliability aspects. Furthermore, MMC will devise and conduct campaigns of accelerated thermo-mechanical stress tests at component, board, and system levels supplemented by comprehensive failure analysis for most efficient determination of the physical lifetime and the failure modes due to the heterogeneous integration in electronic packaging. The results are the essential input to the development and the validation of the digital twins and basis for PHM strategies.

Key contribution

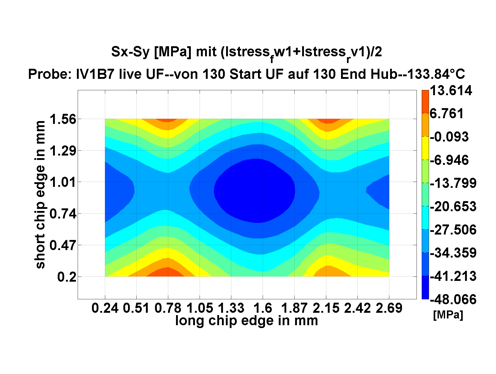

MMC will develop new combined experimental-numerical methodologies for failure prediction and avoidance. These developments and verification testing performed in parallel aim at the development of “digital twins” to achieve product robustness. Reliability issues arising along the processing chain will be considered. A stress sensing system with a fast and easy to use stress monitoring equipment allows to quantify the change in the stress state after manufacturing, at reliability tests, and in service for multiple units. Intrinsic stress induced during fabrication of the electronic packages will be monitored and can later be include in “digital twins”.

The studies focus on the effects of temperature cycling, moisture swelling, and molding. In-situ readings of the stress chip are determined cyclically during the entire technology process. The methodology under development allow to clearly distinguish between the processing stresses and the stresses induced by thermal or moisture exposure in subsequent use - even as functions of process and design parameters. One focus of this project is to enhance the evaluation of the measurement data for lifetime estimations and big data management with A.I. technology, together with the physics of failure simulations.

Fraunhofer ENAS

Technologie-Campus 3

09126 Chemnitz

Germany

Phone: +49(0)371-45001-220

E-Mail: Rainer.Dudek@enas.fraunhofer.de

www.enas.fraunhofer.de