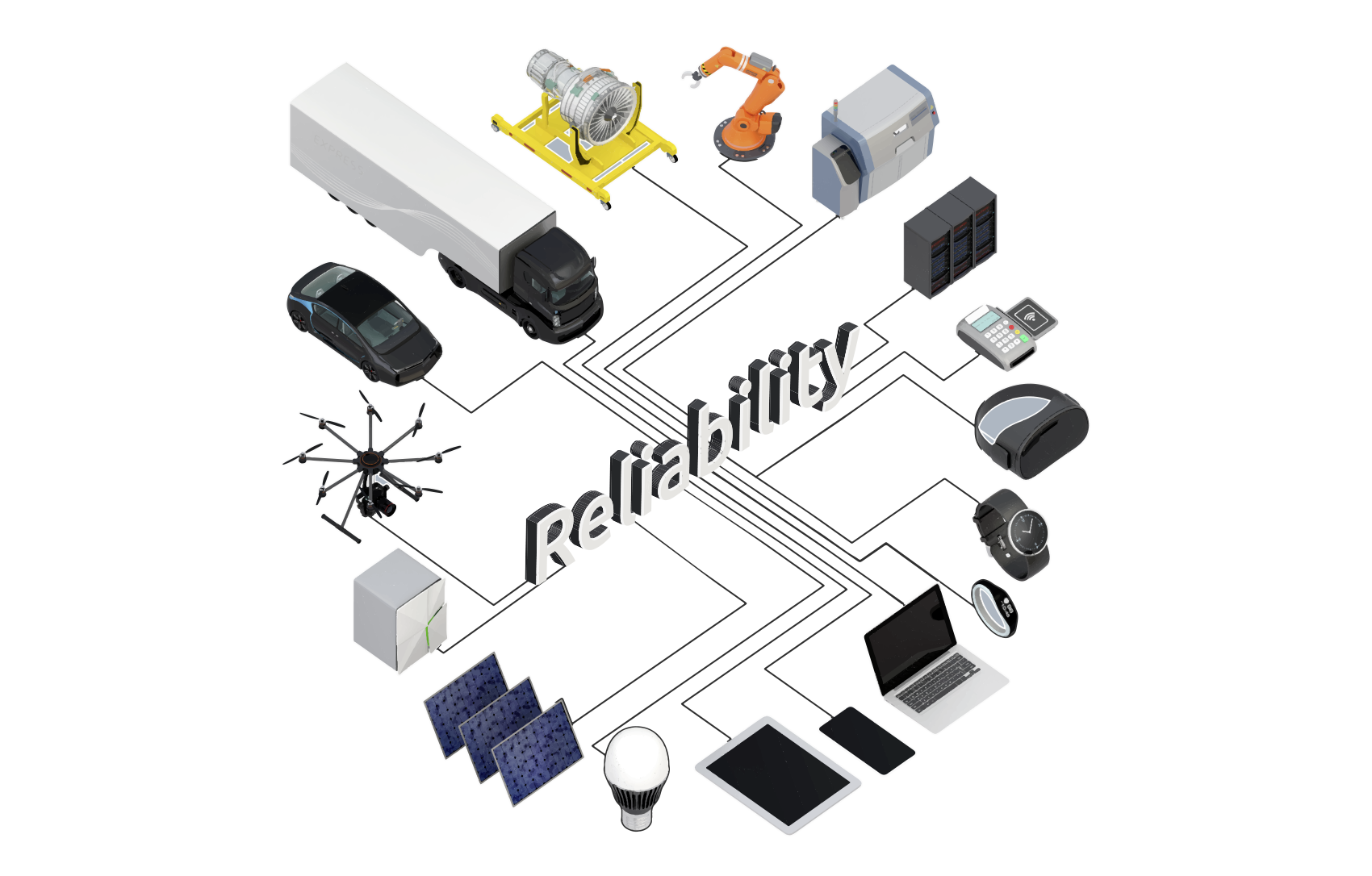

Today’s trend is towards higher system integration driving increasing compactness and complexity and all at acceptable cost. Reliability is challenged on device and system level and faces exceptional requirements in respect to innovative applications. This requires customer acceptance but lead to their satisfaction. Reliability must be guaranteed, when using systems in new and critical environments (corrosive chemicals, extreme temperatures), whereby new materials must be used.

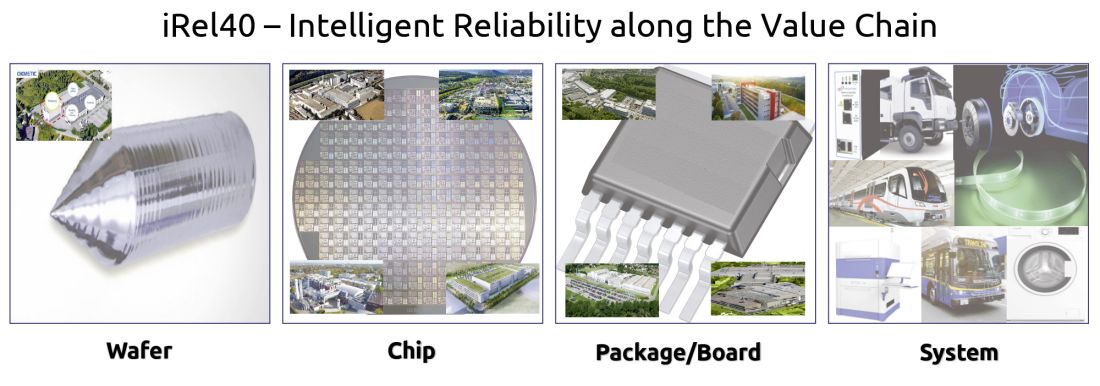

In iRel40 75 partners from 13 countries will collaborate along the value chain from wafer production to system integration and combine their strength to enhance reliability! The project is structured in 6 technical work packages. In WP1 specifications and requirements are studied. WP2 and WP3 will work out the basics on modelling, simulation, materials and interfaces based on test vehicles. In WP4 we apply the gained knowledge to industrial pilots with focus on volume production. In WP5 we apply the knowledge on industrial pilots related to testing.

In WP6 application use cases are manufactured and all project results are assessed and validated. This will allow us to develop reliable electronic components and systems faster. Developed processes can be transfered to production with high speed. Fundamental understanding by Physics of Failure and use of Artificial Intelligence methods will push overall quality levels and reliability specifically.